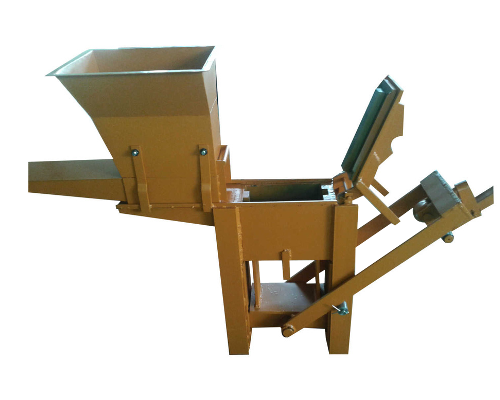

The first attempts for compressed soil bricks were tried in the early days of the 19th century in Europe. The architect François Cointereaux precast small bricks of rammed soil and he used hand rammers to compress the humid soil into a small wooden mould held with the feet. The first steel stabilsed soil press machine which has been produced in the world in the 1950’s was the Cinvaram. It was the result of a research programme for a social housing in Colombia to improve the hand moulded & sun dried brick (adobe). This press could get regular bricks in shape and size, denser, stronger and more water resistant than the common adobe. Since then many more types of soil blocks machines were designed and many laboratories got specialised and skilled to identify the soils for buildings. Many countries in Africa especially East Africa have been using a lot this technique. The soil, raw or stabilized, for a compressed earth brick is slightly moistened, poured into a brick machine (with or without stabiliser) and then compressed either with a manual or motorized press. CEB can be compressed in many different shapes and sizes . Compressed earth blocks can be stabilised or not. But most of the times, they are stabilised with cement or lime. Therefore, we prefer today to call them Compressed Stabilised Earth Blocks (CSEB). Kafum stabilised soil brick machine are manufacture by our highly experienced engineers to ensure all bricks produced using Kafum Issb technology meet international standards

The first attempts for compressed soil bricks were tried in the early days of the 19th century in Europe. The architect François Cointereaux precast small bricks of rammed soil and he used hand rammers to compress the humid soil into a small wooden mould held with the feet. The first steel stabilsed soil press machine which has been produced in the world in the 1950’s was the Cinvaram. It was the result of a research programme for a social housing in Colombia to improve the hand moulded & sun dried brick (adobe). This press could get regular bricks in shape and size, denser, stronger and more water resistant than the common adobe. Since then many more types of soil blocks machines were designed and many laboratories got specialised and skilled to identify the soils for buildings. Many countries in Africa especially East Africa have been using a lot this technique. The soil, raw or stabilized, for a compressed earth brick is slightly moistened, poured into a brick machine (with or without stabiliser) and then compressed either with a manual or motorized press. CEB can be compressed in many different shapes and sizes . Compressed earth blocks can be stabilised or not. But most of the times, they are stabilised with cement or lime. Therefore, we prefer today to call them Compressed Stabilised Earth Blocks (CSEB). Kafum stabilised soil brick machine are manufacture by our highly experienced engineers to ensure all bricks produced using Kafum Issb technology meet international standards