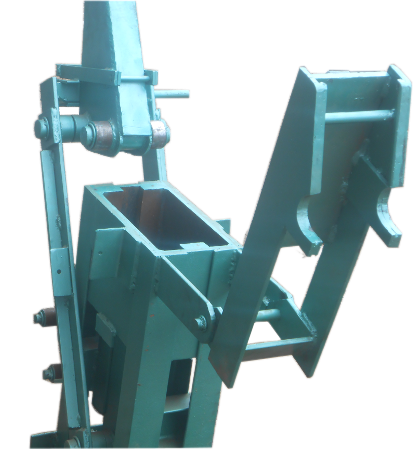

Interlocking Stabilised Soil Block (ISSB) technology has been gaining recognition in East Africa, particularly in Kenya. The material and method of construction has the advantages of low cost and minimal environmental impact, while providing comparable quality to conventional fired brick construction. at kafum engineering we are committed to designing and manufacturing interlocking stabilized soil brick machines (ISSB) in Kenya using high quality material yet maintaining the affordability factor. this has seen many young people start micro stabilized soil brick manufacturing plants, creating jobs and providing livelihood for thousands of families in Kenya. also known as makiga stabilized soil block machine, many Kenyans call it interlocking mad block making machine, issb machine, interlocking brick machine though you will find more names for the machine in different parts of Kenya. listed below is the block making machine specification.

Interlocking Stabilised Soil Block (ISSB) technology has been gaining recognition in East Africa, particularly in Kenya. The material and method of construction has the advantages of low cost and minimal environmental impact, while providing comparable quality to conventional fired brick construction. at kafum engineering we are committed to designing and manufacturing interlocking stabilized soil brick machines (ISSB) in Kenya using high quality material yet maintaining the affordability factor. this has seen many young people start micro stabilized soil brick manufacturing plants, creating jobs and providing livelihood for thousands of families in Kenya. also known as makiga stabilized soil block machine, many Kenyans call it interlocking mad block making machine, issb machine, interlocking brick machine though you will find more names for the machine in different parts of Kenya. listed below is the block making machine specification.

Two designs soil or concrete materials.

Portable

Manual

Cheap, Durable easy to operate

Total Mass soil Machine -140Kg

Concrete and Soil 300-340Kg

Pressure 60-100 tons

Typical Block & Brick Size 290mm x 140mm x 115mm, 300mm, 150mm, and 100mm

Concrete block has been used as a building material for more than a century. In Kenya, concrete block is also a common building material frequently used in home construction. Generally, concrete blocks are fabricated using products such as Portland cement, different aggregates such as stone or quartz, and water. The chances are also high that you've seen many concrete block homes that don't look like they're made out of concrete block because of their external facings or coverings. A concrete block is referred to as a concrete masonry unit, or CMU, in the construction industry. Concrete blocks can be solid or hollow, with two or three cores or voids, depending on the Block Making Machine used. The blocks also come in a range of standard shapes.

Generally, concrete blocks measure 16 inches long by 8 inches wide by 8 inches high, though their actual widths and heights are a quarter-inch less. Concrete blocks are lightweight, durable and fireproof, making them a useful home-building material. Kafum Engineering Services has a reputation of fabricating Block Making Machines of high quality both Manual and Automatic at customer's friendly prices without compromising on quality of the manufactured block making machine. kafum brick making machines are built with high quality steels, and by a high quality experienced team to give them their professional quality finish, they will require very little maintenance. They will require very little training, and all machines come with a instruction manual to help you on your way to producing quality bricks & blocks. when it come to cost We aim to bring your business affordable block making solutions. We supply high quality brick making machines without the high price tag attached. Quality block makers doesn't have to be expensive. Plate type, cabro/paving, Egg Laying or mobile and steel Block molds

Our concrete mixers are made at our light industries Kenya factory to very high specifications suitable for rugged, long term and continuous use. Having a long standing success record in this field, we stock all parts and provide a comprehensive back up service.The 410 litre drum Concrete mixer with 6.5 HP, slow speed diesel engine has a mixing capacity of 430 litres and comprises the following:

Either Electric, Diesel, or petrol run. With state of the art Gears that are durableHeavy duty cast iron Drum capacity 500L

Mixed Capacity 430L

Concrete Production level per hour 100L

Electric Motor Rating 3Hp

Diesel/Petrol Engine rating 8.5Hp

Engine Tasha. We boast of offering best prices on Concrete mixers in Kenya and beyond

According to Wikipedia Block paving is a commonly used decorative method of creating a pavement or hardstanding. The main benefit of blocks over other materials is that individual cabros can later be lifted up and replaced. This allows for remedial work to be carried out under the surface of the paving without leaving a lasting mark once the cabros have been replaced. Typical areas of use would be for driveways, pavement, patios, town centres, precincts and more commonly in road surfacing. cabros are typically made of concrete, though other composite materials are also used. Each has its own means of construction. The biggest difference is the way they set hard ready for use. A concrete block has to be allowed to set. The concrete paving blocks are a porous form of blocks formed by mixing small stone hardcore, dyes, cement and sand and other materials in various amounts. Many block paving manufacturing methods are now allowing the use of recycled materials in the construction of the paving blocks such as crushed glass and crushed old building rubble. Here at Kafum Engineering Services we manufature the best cabro block machines in kenya at customer friendly prices. Looking for where to buy a high quality Cabro block machine? Look no further

According to Wikipedia Block paving is a commonly used decorative method of creating a pavement or hardstanding. The main benefit of blocks over other materials is that individual cabros can later be lifted up and replaced. This allows for remedial work to be carried out under the surface of the paving without leaving a lasting mark once the cabros have been replaced. Typical areas of use would be for driveways, pavement, patios, town centres, precincts and more commonly in road surfacing. cabros are typically made of concrete, though other composite materials are also used. Each has its own means of construction. The biggest difference is the way they set hard ready for use. A concrete block has to be allowed to set. The concrete paving blocks are a porous form of blocks formed by mixing small stone hardcore, dyes, cement and sand and other materials in various amounts. Many block paving manufacturing methods are now allowing the use of recycled materials in the construction of the paving blocks such as crushed glass and crushed old building rubble. Here at Kafum Engineering Services we manufature the best cabro block machines in kenya at customer friendly prices. Looking for where to buy a high quality Cabro block machine? Look no further

A plate compactor is a piece of construction equipment used to smooth and level the earth. It consists of a heavy steel plate mounted to the base of a machine, and bears some resemblance to a push-style or riding lawn mower. The plate compactor uses either a vibrating or pounding action to flatten the land beneath the plate in preparation for paving, landscaping or other work. These machines can be purchased for home or business use.

Builders and landscapers can choose from several types of plate compactor models, which differ in size, power, and operating mechanism. Vibrating units simply vibrate the plate to force air pockets out of the soil, resulting in compaction. In general, the larger the plate compactor, the greater pressure it is able to produce. Kafum engineering services offers quality, long-lasting plate compactors at amazing prices. Depending on the job, choose from reversible plate compactors, which are good in confined areas, and ones with built-in water tanks, which are great for small jobs. Plate compactors work with all types of materials including asphalt, dirt and cement. From contractors to handymen, with the discount prices offered by kafum, it usually makes more sense to buy a compactor rather than rent it.

Plate Compactor with 8.5 engine with high power and low fuel consumption powers the 21 1/2in. x 16 1/2in.

* Ductile iron base plate provides better durability

* Open plate provides self cleaning

* Easy-remove water tank with built-in valve

* Radius bass plate for easy access to corners

* Centrally located lifting bar and built-in wheel

Terrazzo flooring in one of the oldest and the most durable form of flooring. Here in Kenya the technology was brought in by Italians in the 1960s.It is said that terrazzo lasts the life time of the building provided it is laid using the right procedure and maintained properly. At kafum engineering we fabricate high quality terrazzo machines that are easy to use and maintain. The biggest worry of any terrazzo floor expert is where to buy a terrazzo grinding machine and pocket friendly price. kafum caters for all this

Terrazzo flooring in one of the oldest and the most durable form of flooring. Here in Kenya the technology was brought in by Italians in the 1960s.It is said that terrazzo lasts the life time of the building provided it is laid using the right procedure and maintained properly. At kafum engineering we fabricate high quality terrazzo machines that are easy to use and maintain. The biggest worry of any terrazzo floor expert is where to buy a terrazzo grinding machine and pocket friendly price. kafum caters for all this

Electric Motor 3 Hp

Motor Speed: 1400rpm

Motor Type: Induction Motor, Single Phase

Grinding Disc Diameter: 12inches

The Stone Crusher is constructed with heavy ribbed M.S. plates, with strong and thick welding joints.

The Stone Crusher is constructed with heavy ribbed M.S. plates, with strong and thick welding joints.

Accurately machined & aligned, strong bearing housings, very thick, hard and tough adjustable toggle plate, Heat treated, hardened alloy steel main shaft, proper lubrication system, high manganese steel jaw plates, hard faced side plates, impart a long life to the machine. Spring loaded safety tiebar protects Jaw stock

Concrete vibrators consolidate freshly poured concrete so that trapped air and excess water are released and the concrete settles firmly in place in the formwork. Improper consolidation of concrete can cause product defects, compromise the concrete strength, and produce surface blemishes such as bug holes and honeycombing. Vibrating tables or shake tables are sometimes used to test products to determine or demonstrate their ability to withstand vibration. Testing of this type is commonly done in the automotive, aerospace, and defense industries. These machines are capable of producing three different types of vibration profile sine sweep, random vibration, and synthesized shock. In all three of these applications, the part under test will typically be instrumented with one or more accelerometers to measure component response to the vibration input. A sine sweep vibration profile typically starts vibrating at low frequency and increases in frequency at a set rate (measured in hertz per second or hertz per minute). The vibratory amplitude as measured in gs may increase or decrease as well. A sine sweep will find resonant frequencies in the part. A random vibration profile will excite different frequencies along a spectrum at different times. Kafum engineering services offers affordable, effective and durable vibrating tables to suit any industrial or construction application. From settling material for shipping or consolidating concrete, kafum has a Vibrating Table solution to meet your needs.

We have the shortest vibrating table lead times on the market. That means that you will have the vibrating tables that you want, exactly when you want them.

Kafum Vibrating Tables Help Reduce Costs

Concrete and Construction Applications

Reduce the need to trowel during pours

Reduce or eliminate the need to hand finishing to remove flaws caused by trapped air

Dramatically improve product quality and reduce defects without increasing costs

Industrial Applications

Put more material into smaller containers

Ship less air

Reduce overflow and spillover waste at filling stations

Perform fatigue testing

Top quality, fastest delivery

Size 4”x4”

Electric Motor 5Hp

We also custom make according to your use. We know that you are seaching for vibration tables sale in Kenya. Search no more. We have the best price on vibration tables in Kenya and the africa region at learge