Introduction

Brick making remains an important industry in many rural and peri-urban areas, Often there are large numbers of producers and the quality of bricks produced can vary greatly depending with the method of production and the equipments used. Stabilised Soil Brick technology (also known as Stabilized Compressed Earth Block (SCEB)) allows producers to easily manufacture higher quality bricks and as a result receive a higher income for themselves at the same time enabling home owners save on building cost by over 40%

What are Stabilised Soil Bricks?

Stabilised soil bricks technology offers a cost effective, environmentally sound masonry system. The product has a wide application in construction and is manufactured by compacting earth (murram/sub-soil) mixed with a stabilizer such as cement or lime. Anumber of manual machines are available which compact the soil to attain dense, even sized masonry. The bricks are then laid out in the sun and cured rather than being fired. Some SSB technology like the one deployed by kafum engineering services also includes an interlock (called ISSB) resulting in lower mortar costs. The bricks have four key advantages over traditional bricks:

Advantages:

1) Build Quality: SSB allows users to produce uniform blocks of greater strength than typical fired blocks. this provide better thermal insulation.

2) Financial: The total cost of building a structure with SSB is 30%-40% cheaper than building with fired bricks because far less mortar is required, structures don’t have to be plastered, and bricks can be made on site so transportation costs are minimized.

3) Environmental: Because SSBs are cured in the sun, the need for fuel wood is eliminated, helping curb deforestation rates.

4) Appearance: The bricks have an appealing aesthetic with an elegant profile and uniform size that doesn’t require plastering.

How are the bricks made? The Process:

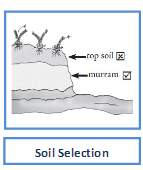

1)Soil selection

A site evaluation has to be carried out to make sure you have suitable soil for brick making. A number of cheap and easy tests have been created to effectively test soil quality. You are looking for sub-soil with few stones of a fine quality.

2)Stabilisation & Mix Preparation:

First the soil must be sieved to remove foreign elements from the soil. Then the soil must be mixed with a stabiliser to maximize strength – usually cement, but lime can also be used. The stabiliser must be thoroughly mixed with the soil and then water added.

3)Compaction

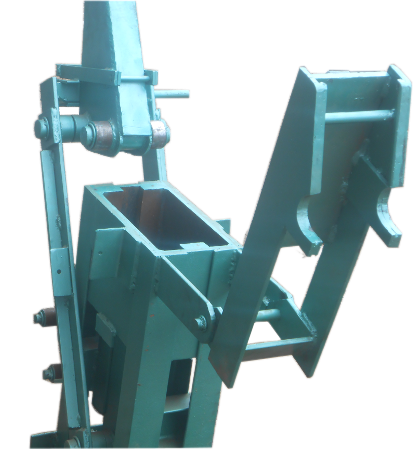

The soil mixture then needs to be compacted to ensure strength and quality. Generally a manual hand press is used. The bricks need to be carefully removed from the mould and stacked correctly.

4)Curing

The bricks are then left in the sun to cure (no firewood needed!) and water is sprinkled to aid curing The bricks must then be stored correctly, often under sheeting, awaiting transportation if not molded on the construction site.

NB 28 days after manufacture, the bricks are ready for selling. SSB can also be used for any on-site construction to lower your own costs

What’s required to start a stabilized soil brick business?

A brick press (a stabilized soil block machine) will be required for compaction, and must be sourced. A kafum interlocking stabilised soil brick machine cost only kshs 85 thousands

A brick press (a stabilized soil block machine) will be required for compaction, and must be sourced. A kafum interlocking stabilised soil brick machine cost only kshs 85 thousands- A site evaluation then has to be held to ensure enough sub-soil is available to make large quantities of bricks. Importing soil is expensive and so availability of sub-soil is a priority.

- Knowledge those involved must understand how you produce SSBs. They can either be trained by an experienced SSB maker, or learn through a number of guides found in this website

- Other tools needed may already be available, if not, they too need to be purchased.

- Capital also has to be found to purchase the required cement

Background and History

The first attempts for compressed earth blocks were tried in the early days of the 19th century in Europe. The architect François Cointereaux precast small blocks of rammed earth and he used hand rammers to compress the humid soil into a small wooden mould held with the feet.

The first steel manual press which has been produced in the world in the 1950’s was the Cinvaram. It was the result of a research programme for a social housing in Colombia to improve the hand moulded & sun dried brick (adobe). This press could get regular blocks in shape and size, denser, stronger and more water resistant than the common adobe. Since then many more types of machines were designed and many laboratories got specialised and skilled to identify the soils for buildings. Many countries in Africa as well as South America, India and South Asia have been using a lot this technique.

The soil, raw or stabilized, for a compressed earth block is slightly moistened, poured into a steel press (with or without stabiliser) and then compressed either with a manual or motorized press. CEB can be compressed in many different shapes and sizes

Compressed earth blocks can be stabilised or not. But most of the times, they are stabilised with cement or lime. Therefore, we prefer today to call them Compressed Stabilised Earth Blocks (CSEB).

The input of soil stabilization allowed people to build higher with thinner walls, which have a much better compressive strength and water resistance. With cement stabilization, the blocks must be cured for four weeks after manufacturing. After this, they can dry freely and be used like common bricks with a soil cement stabilized mortar.